SMT Assembly

Micron’s experienced SMT Assembly team focuses on automated production of multi-layered Surface Mount Assemblies. Our SMT Manufacturing Line is fully computerized to allow for extreme accuracy and high throughput but our capabilities include fully manual production if required for through hole parts, complicated components, small lots or prototype productions. Read more…

View the main steps in our SMT Assembly process below or call us at (781) 949-3500 to discuss your assembly requirements.

Programming

The first step is our SMT Assembly Line process is Programming the PCB. Before component packages are programmed for assembly READ MORE >>

Stencil Printing

After all components have been programmed and setup solder paste is applied to each PCB on the Stencil Printer. The first READ MORE >>

Machine Assembly

Next in our SMT line components are placed on the printed circuit board via the Pick and Place Machine. READ MORE >>

Aqueous Cleaning

All PCB Assemblies undergo Aqueous Cleaning at several critical points during the SMT process, especially after any soldering is completed READ MORE >>

Secondary Assembly

Our highly skilled staff has the manual production capabilities to exceed your assembly requirements. Micron specializes in both SMT and READ MORE >>

Reflow

At the end of our SMT line is Heller Industries’ newest generation of reflow oven, the 1500W. This unit provides READ MORE >>

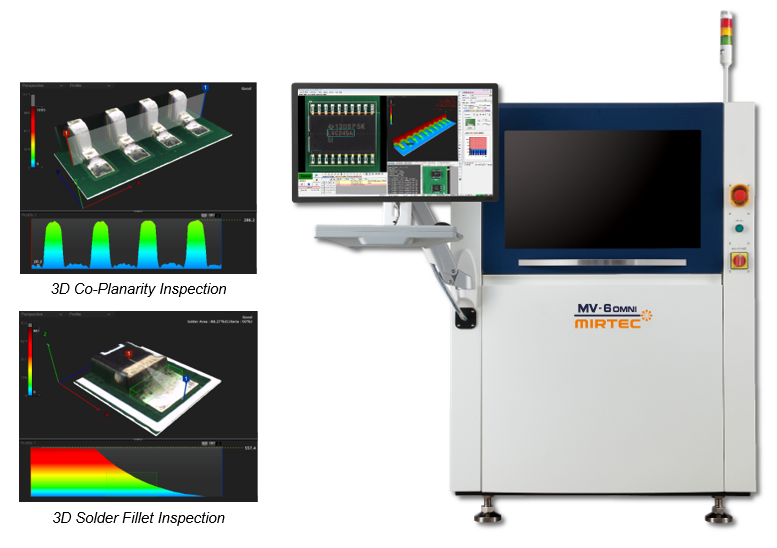

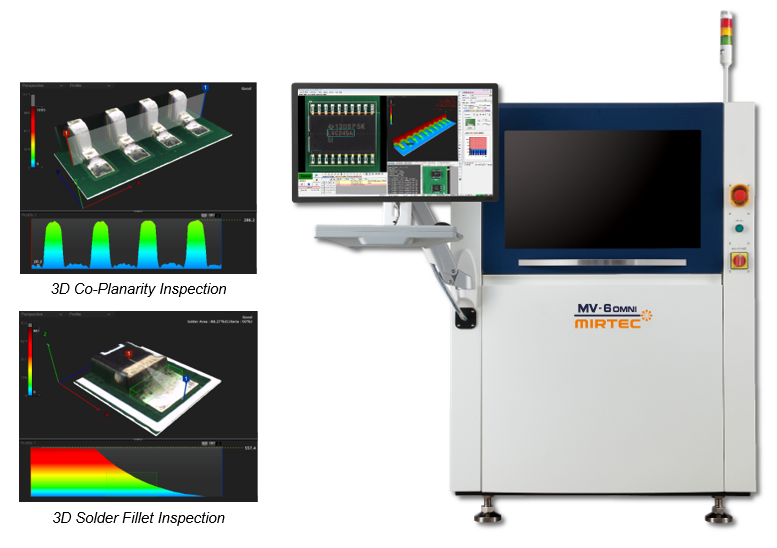

Quality Assurance

Our Quality Assurance Technicians have the experience necessary to maximize inspection throughout the SMT Assembly Process. After each major step READ MORE >>

Packaging

All PCB Assemblies are placed in anti-static packaging before delivery. All boards are given one last wash and touch up before READ MORE >>