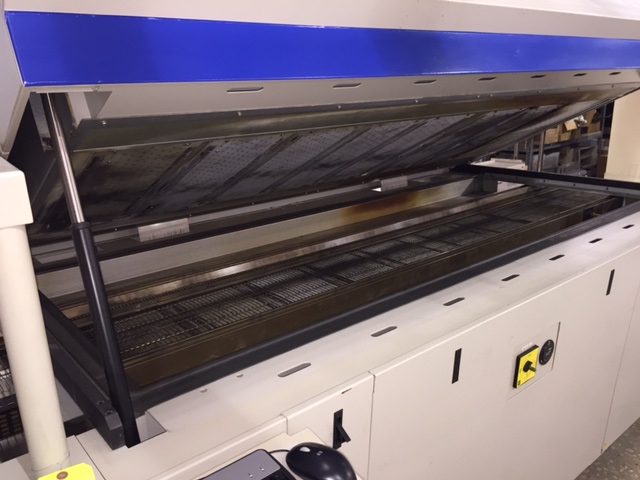

Heller 1707 MKIII

Heller Industries has been pushing the envelope in oven technology for over 30 years, and we’ve been using their products for over 20. Micron’s latest Heller installation is the 1707 MKIII. The 1707 provides all of the latest technology including process control, conveyor system, heating modules, and cooling module.

Process Control

In addition to PID controllers used to monitor and adjust the oven temperatures, the 1707 MKIII has process control software powered by ECD (home of M.O.L.E. thermal profilers). Oven and Process Cpk are tracked, and product traceability is reported.

Conveyor System

Both an edge hold conveyor and a mesh belt conveyor are part of the two-fold conveyor system in the 1707 MKIII. The edge hold can support a PCB assembly with as little as 3(mm) edge clearance, and the mesh belt does not require space between the PCB assemblies.

Heating Modules

Accuracy of the temperature controller is plus or minus 0.1 degrees Celsius and cross-belt tolerance is within plus or minus 3.0 degrees Celsius. These tight temperature ranges are accomplished using Nichrome heater material and calcium silicate insulation.

Cooling Module

A “blow thru” cooling module is used in the final cooling zone to provide cooling rates greater than 3 degrees Celsius per second on even the largest land grid array components.

New SMT Lines » Heller 1707 MKIII